Overview

Prolux Electrical Contractors partnered with Walker Corporation to deliver electrical infrastructure upgrades, facilitating the installation of Electric Vehicle (EV) chargers in the multi-level car park of Tower 5, Collins Square—one of Melbourne’s premier commercial precincts. The project required a complex installation within a live environment, whilst balancing safety, compliance and ensuring minimal disruption to the existing tenancies.

Scope of Works

Prolux delivered a comprehensive suite of electrical works, including:

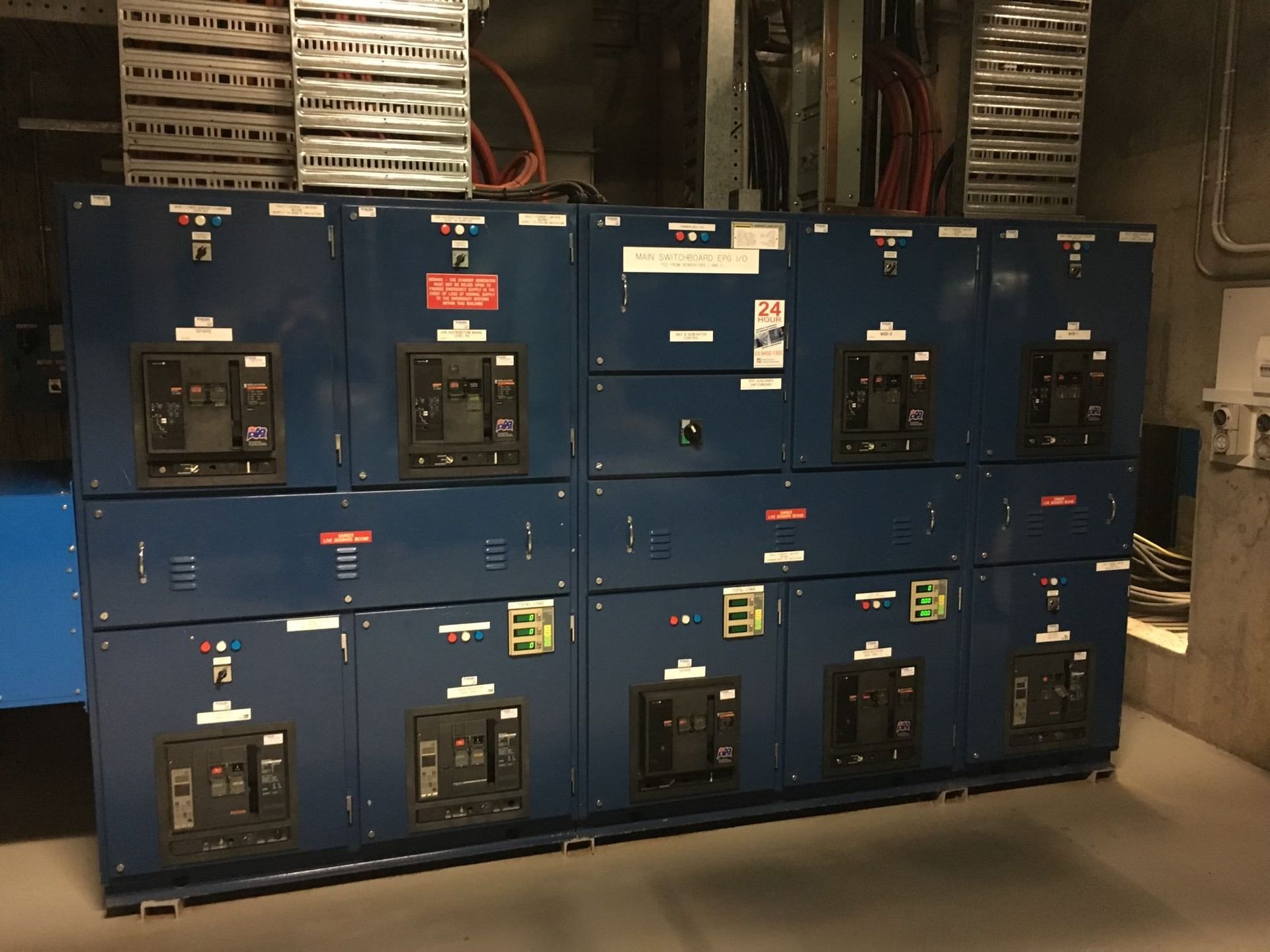

• Installation of a new 400A Circuit:

Supplied and installed a 400A breaker in the spare chamber of the existing Main Switchboard (MSB), ensuring safe shutdowns and full coordination with CitiPower for all authority related works and approvals.

• Metering & Integration:

Installed a Schneider PowerLogic PM5350 sub-meter with BMS integration and NABERS-compliant validation. Prolux also managed the installation of an authority meter with CTs, coordinating the retailer account setup via the client’s utility consultant.

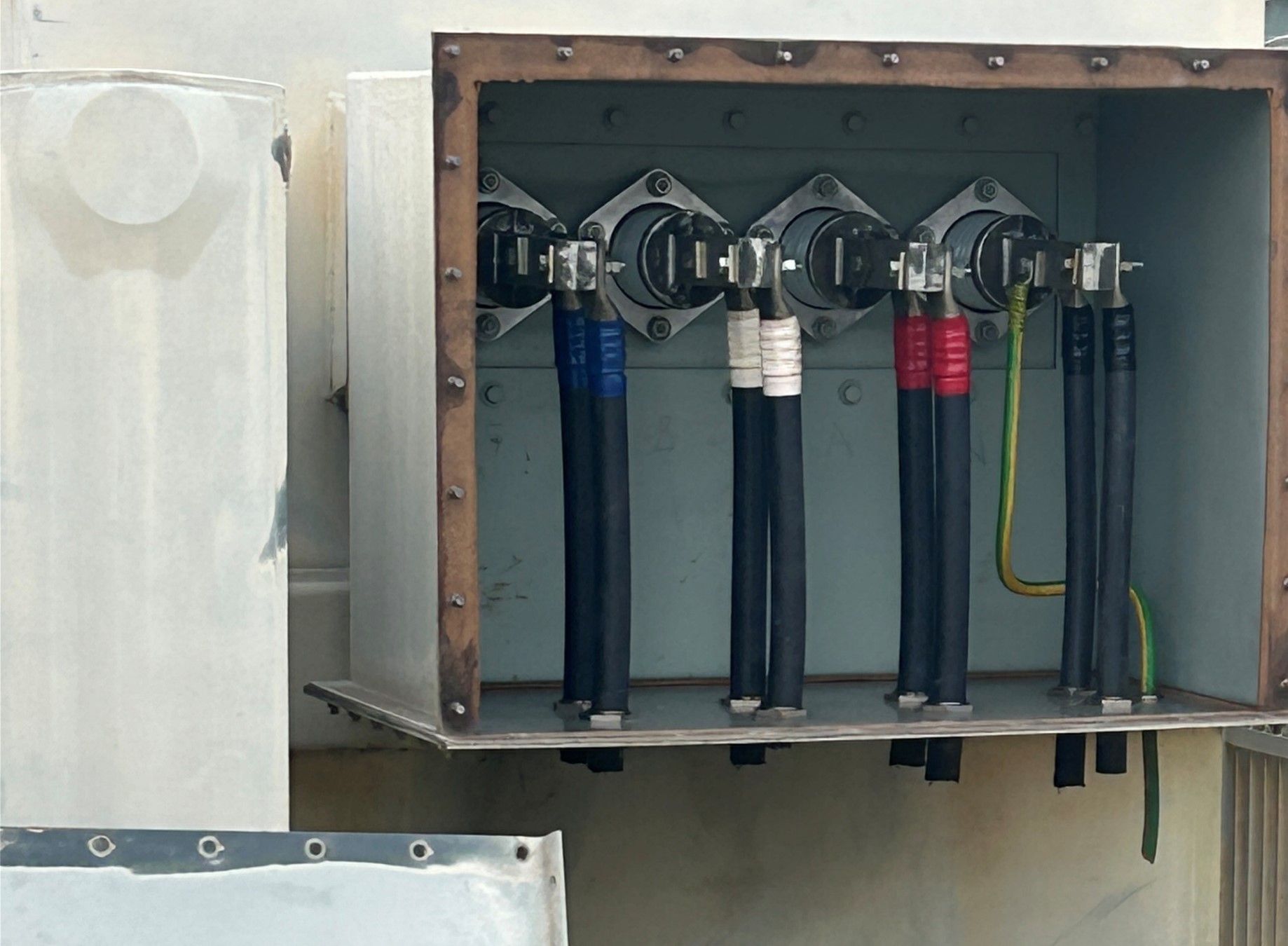

• Sub-Mains and Cable Infrastructure:

Installed a 250A three-phase sub-main to the new Charger Distribution Board, incorporating structural slab penetrations with fire-rated sealing and engineering validation.

• Cable Tray and Impact Protection:

Installation of cable trays and cable protection barriers in the car park to prevent impact damage and maintained clearance above car park services and sprinklers.

• Future-Proofing:

Ensured penetrations and terminations were future-ready, with provisions for additional EV Chargers in the future, without the need for any building isolations.

• Monitoring and Load Management:

Installed Current Transformers to monitor the MSB’s incoming supply, enabling integration with the site's Load Management System (LMS).

Challenges & Solutions

• Prolux worked out-of-hours to minimise disruption, coordinating shutdowns with all stakeholders and maintaining safe temporary lighting throughout.

• Managed strict NABERS metering protocols and seamless integration into the building’s BMS, ensuring long-term sustainability compliance.

• Penetration through structural slabs required close coordination with the structural engineer and real-time adjustment to avoid beams and maintain structural integrity.

Outcome

Prolux successfully delivered the complex infrastructure upgrade, positioning Tower 5, Collins Square for the future of electric mobility. The project demonstrates Proulx’s’ capability in delivering large-scale EV charger readiness works in commercial environments—safely, compliantly and with minimal disruption, enhancing sustainability and future-proofing the property for increasing EV adoption.

Why Prolux?

Prolux Electrical Contractors are at the forefront of commercial EV charger infrastructure solutions. With extensive experience in power upgrades, switchboard works and smart integration, they are trusted by leading Property Managers and developers to deliver reliable future-ready EV charging solutions.